What Standards Must Marine Hatches Comply with?

Marine hatches play a crucial role in ensuring the safety and functionality of vessels. They serve to secure access to various parts of the ship, for both crew and equipment, while simultaneously protecting against water ingress. To fulfill their purpose, they must comply with specific technical, strength, and sealing standards, which are regulated by industry […]

MIG/MAG Welding vs. TIG Welding: A Comparison

Welding is one of the most important methods of joining materials, and in the welding industry, MIG/MAG and TIG techniques are most commonly used. These two methods differ not only in process but also in application, level of precision, and type of materials used. Both MIG/MAG and TIG have their advantages and disadvantages, which make […]

Shipbuilding Industry – Characteristics

The shipbuilding industry plays a crucial role in the global economy, dealing with the design, construction, and maintenance of various types of vessels. It encompasses a wide range of activities, from the construction of powerful container ships and tankers, through military vessels, to luxury yachts and passenger ferries. This industry is characterized by a high […]

What Products are Created for the Shipbuilding Industry?

The production of marine hatches, covers, and coaming rings is a crucial element in ship construction and maintenance. These hatches provide access to various parts of the vessel while ensuring watertight integrity and safety. The production process for these components requires precision, appropriate materials, and compliance with international norms and standards. Knowledge about the production […]

Manganese Steel – Characteristics and Applications

![manganese-steel.[1]](https://metal-serwis.pl/wp-content/uploads/2024/05/stal-manganowa.1-1024x683.webp)

Steel, an alloy of iron and carbon, is divided into many grades that differ in chemical composition and properties, determining their diverse applications in industry. The basic classification of steel includes carbon, alloy, and high-alloy steels. Carbon steels are characterized by a carbon content of up to 2.1% and are most commonly used due to […]

What Qualifications Must a Welder Have?

Manufacturing many machine parts, equipment, industrial installations, or structures requires permanent and stable joining of materials to achieve the necessary mechanical load resistance. The most commonly used technology for joining components while maintaining high strength is metal welding. However, appropriate certifications are necessary for preparing welds, ensuring that the entire process will be carried out […]

Where to Use Steel Furniture?

Metals, particularly various types of steel, are materials suitable for producing diverse components that require high resistance to external factors. This includes mechanical stresses such as pressure, bending, or torsion, as well as thermal loads and exposure to chemicals. This is facilitated by numerous technologies that enable specific components to achieve their required dimensions and […]

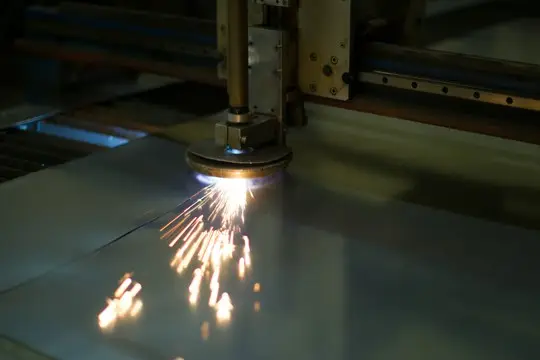

Plasma Cutting vs. Gas Torch Cutting. Comparison

Manufacturing metal elements usually involves the need for proper preparation of the material that will undergo further processing. Among the most important and frequently performed operations is obtaining components with appropriate geometry and dimensions. A commonly used method for this purpose is sheet metal cutting, bars, or other types of metallurgical products or semi-finished products. […]

What is Water Cutting?

Preparing materials for further processing and giving the desired final shape to individual manufactured elements usually requires the use of appropriate cutting technology. It is typically selected based on the possibilities it provides in terms of surface finish precision, cutting line pattern, work speed, and the characteristics of the specific material. One of the solutions […]

What Materials Can be Cut with Water?

Professional processing involves the use of various technological processes depending on the needs and characteristics of the materials used. Cutting is an operation that is essential for most products, allowing for the preparation of fragments with appropriate dimensions and shape, as well as facilitating the separation of elements or adapting them to existing requirements. One […]