Blog

What Materials Can be Cut with Water?

Professional processing involves the use of various technological processes depending on the needs and characteristics of the materials used. Cutting is an operation that is essential for most products, allowing for the preparation of fragments with appropriate dimensions and shape, as well as facilitating the separation of elements or adapting

Aluminum – Characteristics, Advantages, Processing Methods

Preparing metal elements involves the need to give them appropriate parameters beforehand, both in terms of the geometry of individual details and surface finish. Usually, both heat treatment, such as hardening, and preceding mechanical processing, including milling or cutting, are indispensable. Aluminum, steel, or copper alloys have slightly different properties,

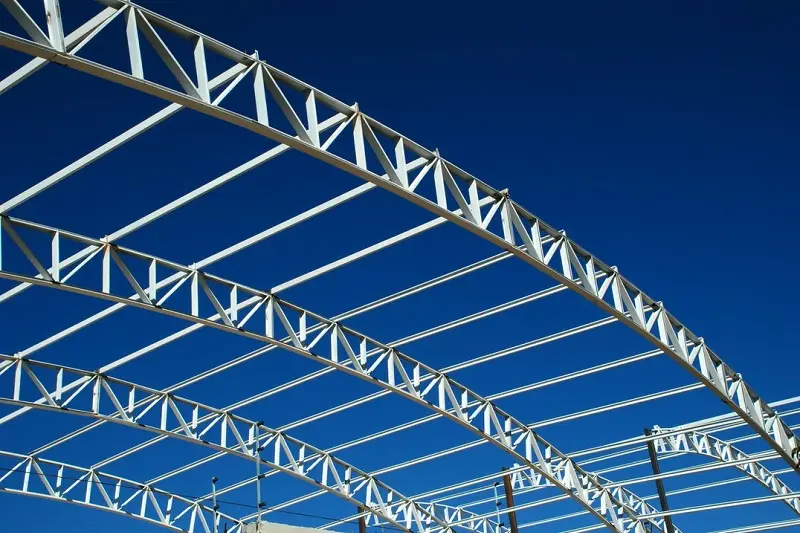

Where are Steel Structures Used?

For many construction and industrial applications, it is necessary to create appropriate load-bearing structures that can support the weight of various equipment or installations, as well as serve for their assembly, operation, or maintenance. Although solutions of this type are extremely diverse in terms of their form, functionality, and size,

Steel structure implementation stages

Individual steel grades are materials offering excellent performance properties, which is why they are widely used in various areas. They are characterized by high resistance to loads and external conditions, while being easy to subject to necessary processing and thus shape, join, and protect. Among extremely popular applications is also

Turning and Milling: a Comparison of Methods

Manufacturing metal components for machines, equipment, and installations that require high precision finishing and low surface roughness demands the use of appropriate processing methods. Most commonly, subtractive machining through cutting is used – a process where excess material is removed from the workpiece in the form of chips using cutting

How much Does Sheet Metal Bending Cost?

Metal processing can involve various operations that allow for shaping individual elements as envisioned by the designer of a given part or device. Among the technological processes performed particularly often is sheet metal bending. Learn how it works and check what method is used to price it.

Welding Methods and Their Characteristics

Welding involves joining elements by heating and fusing material contacts. To perform welding aesthetically and effectively, one must possess appropriate skills. There are several different welding methods, and we present selected ones below.

3 Main Methods of Sheet Metal Processing

Sheet metal is an extremely popular material used in virtually every branch of industry. It serves as a raw material for the production of many tools, precision machine parts, or entire structures. It is durable, resistant to mechanical damage and adverse weather conditions. However, to make good use of its

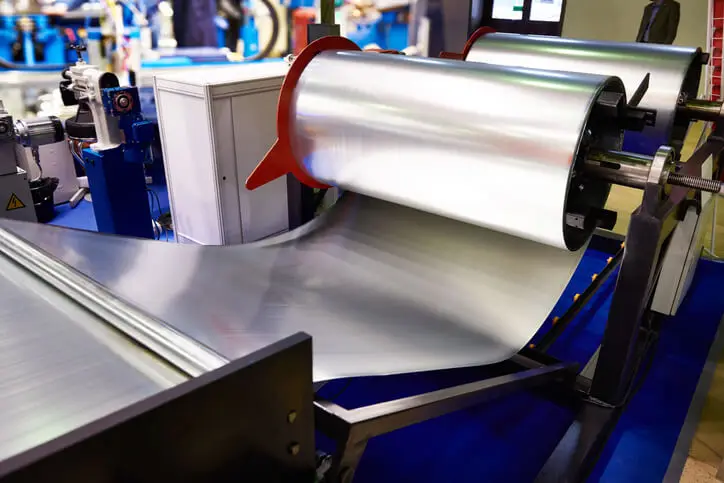

What is Rolling?

Sheet metal rolling is one of the most commonly used methods of plastic processing for various types of metals. During this process, pressure from rotating rollers acts on the sheet metal, causing it to deform. Rolling allows for the production of sheet metal with specific parameters. Moreover, using this method,