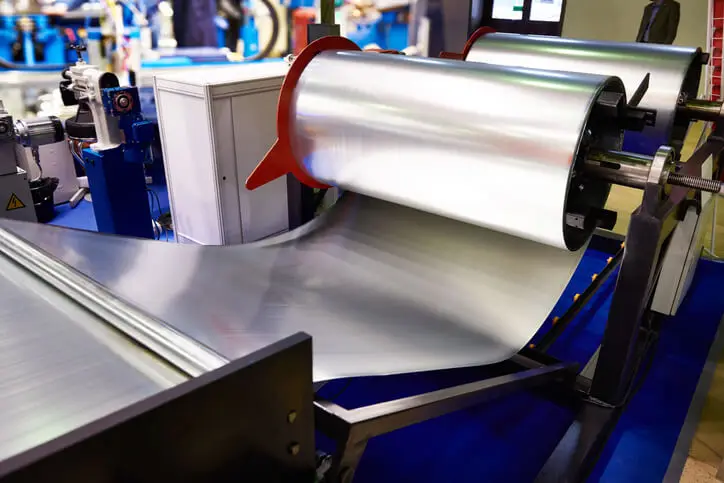

Sheet metal rolling is one of the most commonly used methods of plastic processing for various types of metals. During this process, pressure from rotating rollers acts on the sheet metal, causing it to deform. Rolling allows for the production of sheet metal with specific parameters. Moreover, using this method, it is possible to improve the properties of various types of materials.

How is rolling performed?

Rolling is a process that can be performed either hot or cold. During cold rolling, the rolled elements do not change their properties, as the sheet metal is not heated during processing. Cold rolling is performed on elements that have previously undergone hot processing. The exact process of rolling depends primarily on the raw material, being worked with. Cold rolling is used to produce elements such as pipes, bronze and copper strips, as well as thin sheets. Cold rolling can achieve a very high quality finish.

Hot rolling takes place under elevated temperature conditions, which allows the shape, size, and properties of the processed material to change. The temperature during hot rolling ranges between 1000 – 1300 degrees Celsius

During this process, flat bars, sheets, and strips, as well as rods are produced. Pipes are also manufactured using hot rolling. Elements produced during cold and hot rolling are characterized by high quality, resistance to mechanical damage, and adverse weather conditions.