Manufacturing metal elements usually involves the need for proper preparation of the material that will undergo further processing. Among the most important and frequently performed operations is obtaining components with appropriate geometry and dimensions. A commonly used method for this purpose is sheet metal cutting, bars, or other types of metallurgical products or semi-finished products. Depending on the expected result, various cutting methods can be used. Frequently used methods include different types of thermal cutting, including plasma cutting and gas cutting. Let us examine them more closely.

What should you know about gas cutting?

Gas cutting, also referred to as oxygen cutting, involves heating the material to ignition temperature and then removing the liquefied metal from the resulting gap through appropriate pressure of the supplied stream. The oxygen used is mixed with a combustible gas that is responsible for initiating and maintaining combustion. This is usually acetylene or propane-butane. The advantage of oxygen cutting is the ability to work with

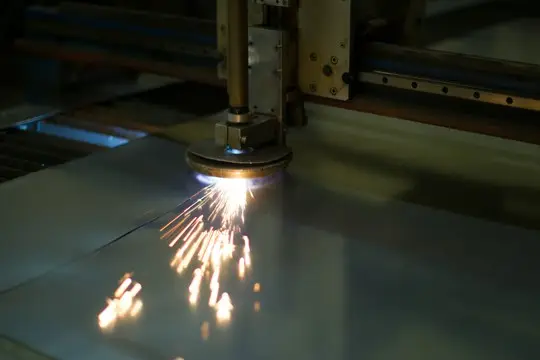

What does plasma cutting look like?

Plasma cutting involves melting and ejecting metal from the cutting gap through the use of a plasma stream, created by an electric arc reaching very high temperature and ionized gas. Its stream allows for ejecting molten metal from the cutting zone. Air or argon, nitrogen, hydrogen, or carbon dioxide are used to generate plasma. It is also possible to use a mixture of argon with helium or hydrogen. Plasma cutting is feasible for carbon steel and alloy steels, aluminum and copper and their alloys, as well as cast iron. The advantage of this technology is high precision and the possibility of use with materials of small thickness.